Innovative refrigerated logistics: the AURORA project as a pioneer

General information on the AURORA - Automated Refrigerated Zero Emission Logistics Operations project

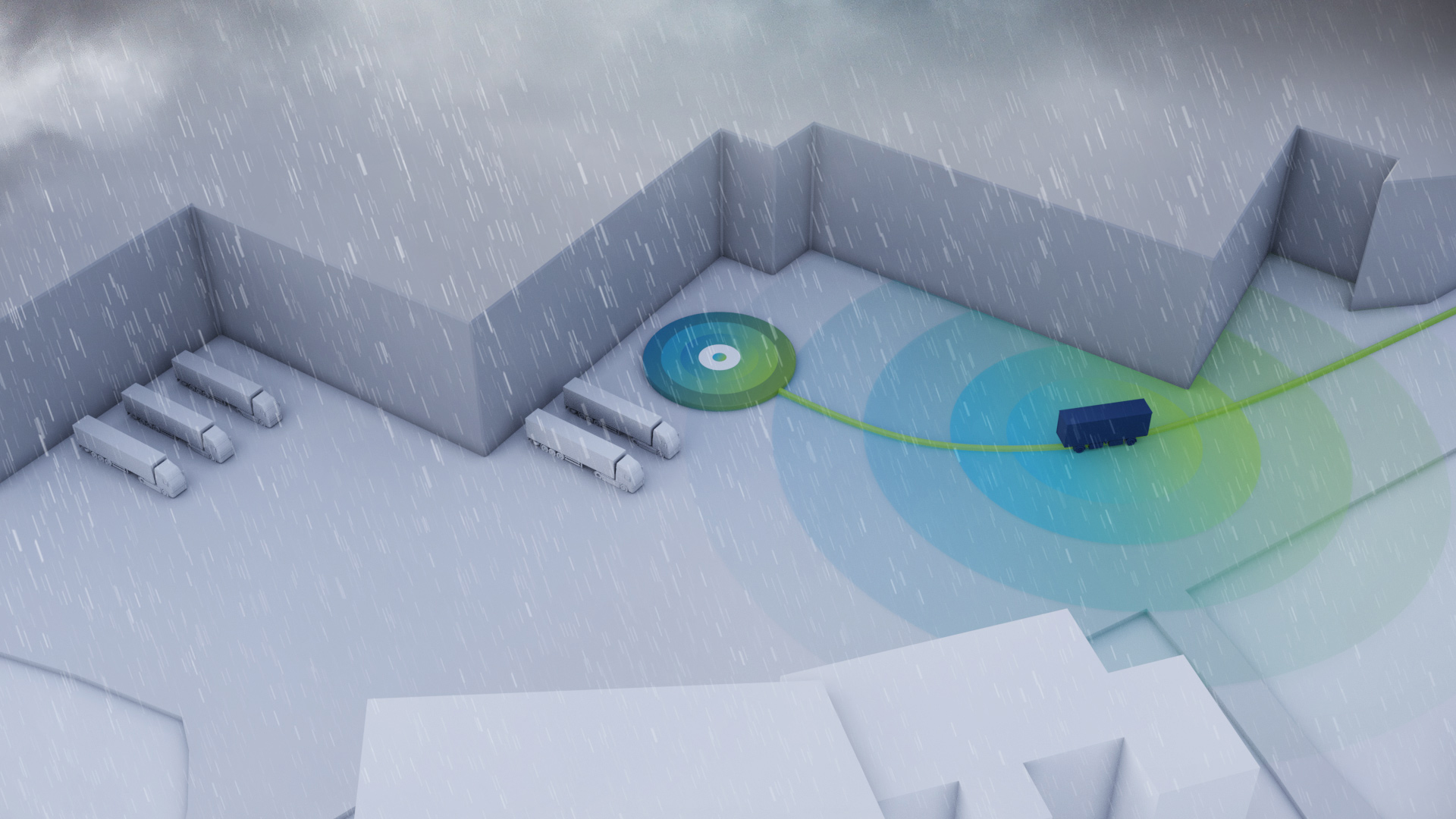

The AURORA – Automated Refrigerated Zero Emission Logistics Operations project aims to develop a safe and robust concept for refrigerated logistics that combines zero-emission technologies with autonomous driving functions. A refrigeration system is integrated into an autonomous vehicle and tested in various realistic scenarios. The AURORA project not only tests driving behavior (steering, braking, acceleration), but also the entire process chain. The first tests will take place in China in October, followed by further tests in Austria at the Digitrans Test Center for Automated Driving in St. Valentin. The vehicle will also be tested in rainy conditions to analyze its driving behavior in poor weather conditions. The tests will show how stable this technology works on Austrian roads and what availability can be achieved under such conditions.

In the course of the project, a vehicle based on Chinese technology, which is already more advanced than the models currently available in Europe, will be tested in Austria for the first time. The automation of the vehicle is based on artificial intelligence, the construction is cost-effective and there is no space for a safety driver.

Project goals

- Minimizing obstacles to the electrification and automation of the (refrigeration-based) transport system

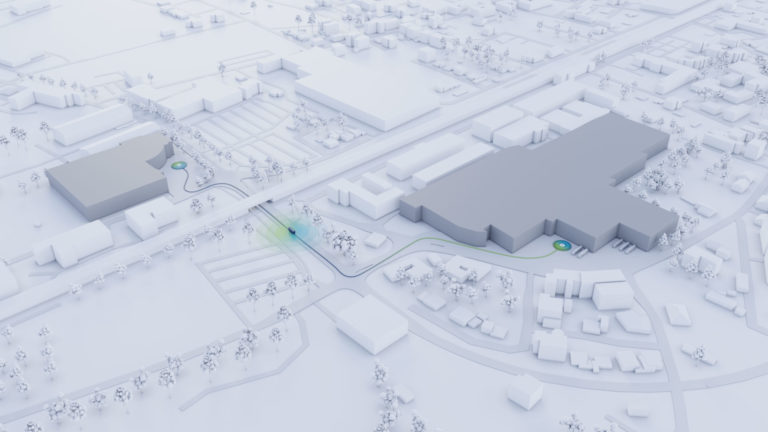

- Enabling the use of automated, emission-free refrigerated logistics in logistics centers and on the road

- Introducing true zero-emission refrigeration technologies in both Jiangsu Province and Austria, setting up twin digital simulation test scenarios of the two locations

- Paving the way for autonomous deliveries that minimize freight costs, improve asset utilization, lower logistics costs and reduce energy consumption

Successful implementation of the project will result in a pilot solution that can be transferred to other logistics tasks in the food industry with minimal adjustments.

The cooperation between China and Austria in this project opens up valuable opportunities to combine the technological strengths of both countries and drive forward innovative solutions.

You might also be interested in

Further Insights

Project RIAMO – rural communities enabled for integrated automated mobility

It involves the implementation of an efficient, automated on-demand shuttle service as part of a grant project. Accordingly, it is intended to provide residents of rural areas with better access to the higher-ranking public transport network.

Autonomous goods transport is coming to Upper Austria

In a practical use case, research is being conducted in Upper Austria with the two project partners BRP Rotax and the freight forwarder Schenker on a public transport section with an autonomous transport vehicle to find a hub-to-hub logistics application suitable for everyday use and independent of weather conditions.

Hub-to-hub transport with autonomous transport systems

In a practical use case, research is being conducted in Upper Austria with the two project partners BRP Rotax and the freight forwarder Schenker on a public transport section with an autonomous transport vehicle to find a hub-to-hub logistics application suitable for everyday use and independent of weather conditions.

Project partner:

Further information:

- Project duration: 2.5 years

- Project start: July 2023

- Funding body: FFG

Share: