Project AURORA:Revolutionizing refrigerated logistics through autonomous transport technologies

Refrigerated transport not only ensures our food supply, but is also essential for the transportation of vital goods such as medicines. Securing this supply chain was a major challenge, especially during the pandemic, but current issues such as the ever-increasing shortage of drivers or short-term staff shortages also make this task a current challenge.

The AURORA project aims to make its contribution here:

By using autonomous refrigerated and transport vehicles, the aim is to make the supply chain more stable and secure. Real refrigeration and logistics applications are being tested in real operations in both China and Austria.

Why China?

Especially during the contact restrictions in the wake of the coronavirus pandemic, supply chains in major Chinese cities almost came to a standstill. It was no longer possible to ensure that people could be supplied. In order to ensure a more stable and secure supply chain in the future, major Chinese cities have decided to use technologies such as autonomous driving.

Moreover, Chinese solutions in the field of autonomous driving are among the leading ones internationally and can provide the most advanced and best field-tested vehicles. After inspecting and testing various vehicle solutions in China, we opted for the Zelos Z5 vehicle.

Transportation of the vehicle from China to Austria

The vehicle was loaded in the city of Suzhou and transported to the port, shipped to Trieste and then brought to Linz by train. Customs clearance was carried out in Schwertberg at Hödlmayr Logistics GmbH.

Test phase in both countries

In recent months, defined refrigerated logistics use cases have been tested following successful simulation. A special feature here is that the tests were carried out without a safety driver in the vehicle and on public roads. The results are particularly impressive.

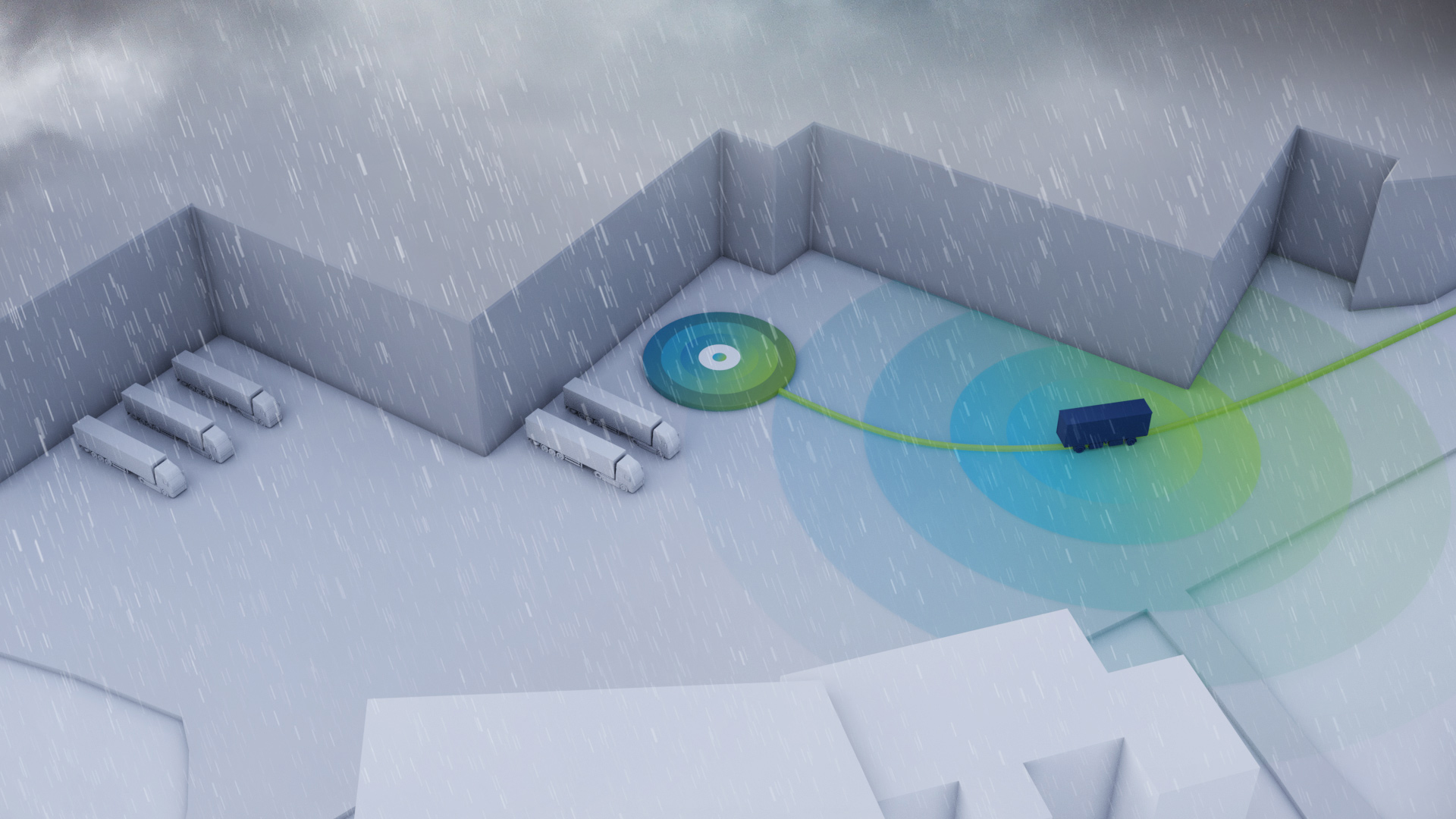

As it is not yet possible in Austria to test automated vehicles without a safety driver on public roads for legal reasons, the tests are carried out at the Digitrans Test Center for Automated Driving in St. Valentin. In order to ensure maximum safety during testing, the vehicle is currently being checked for reliability with the manufacturer after commissioning. A 5-stage test plan developed by Digitrans is used to objectively assess the safety of the vehicle as well as the overall performance of the solution.

After successful completion and a positive vehicle evaluation, the refrigerated logistics use cases relevant to Austria are then simulated in the Digitrans test center for autonomous driving and their feasibility is tested in practice with the Zelos Z5.

You might also be interested in

Further Insights

Autonomous goods transport is coming to Upper Austria

In a practical use case, research is being conducted in Upper Austria with the two project partners BRP Rotax and the freight forwarder Schenker on a public transport section with an autonomous transport vehicle to find a hub-to-hub logistics application suitable for everyday use and independent of weather conditions.

Automated Freight Transport – EU Project AWARD H2020 – the first project year

Insights on the EU project AWARD (All Weather Autonomous Real logistics operations and Demonstrations) by Digitrans project manager Hannes Watzinger. Insights into an exciting and challenging project year in the field of automated freight transport.

Innovative refrigerated logistics: automated logistics in the food industry

For automated food logistics – especially refrigerated logistics – to function smoothly, every link in the process chain must be precisely analyzed and optimized

Project partner:

Further information:

- Project duration: 2.5 years

- Project start: July 2023

- Funding body: FFG

Share: